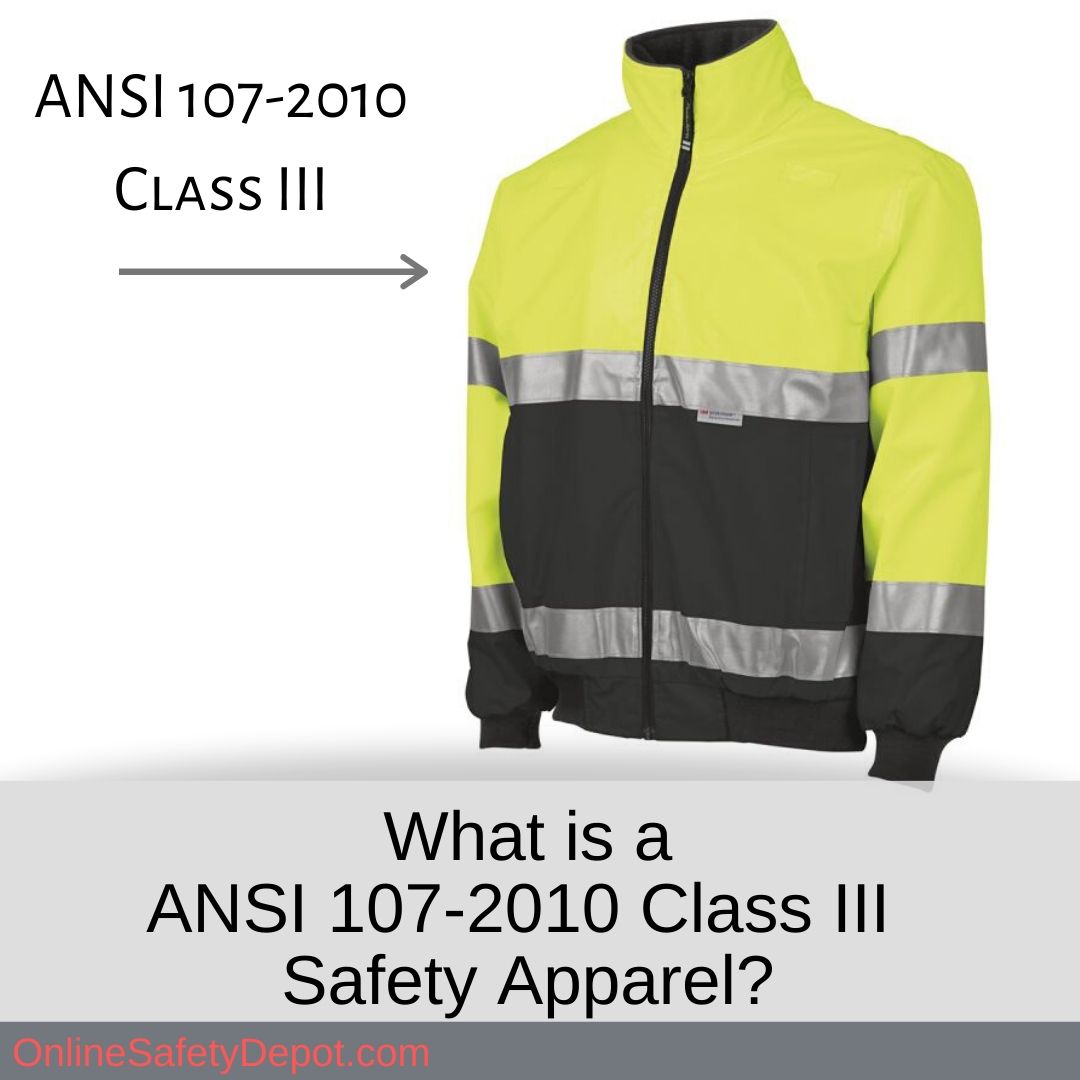

There are several safety regulatory organizations whose purpose is to provide guidelines designed to provide individuals, usually employees or workers, with protection from identified potential hazards associated with the work they perform. The American National Standard for High-Visibility Safety Apparel...

Need help? Call us or text us: (480) 818-9373

-

Shop by category

- Construction Safety (155)

- Facilities Safety (83)

- Fire Safety (360)

- Recreational Safety Products (65)

- Climbing Safety (17)

Search

Category: Featured Products

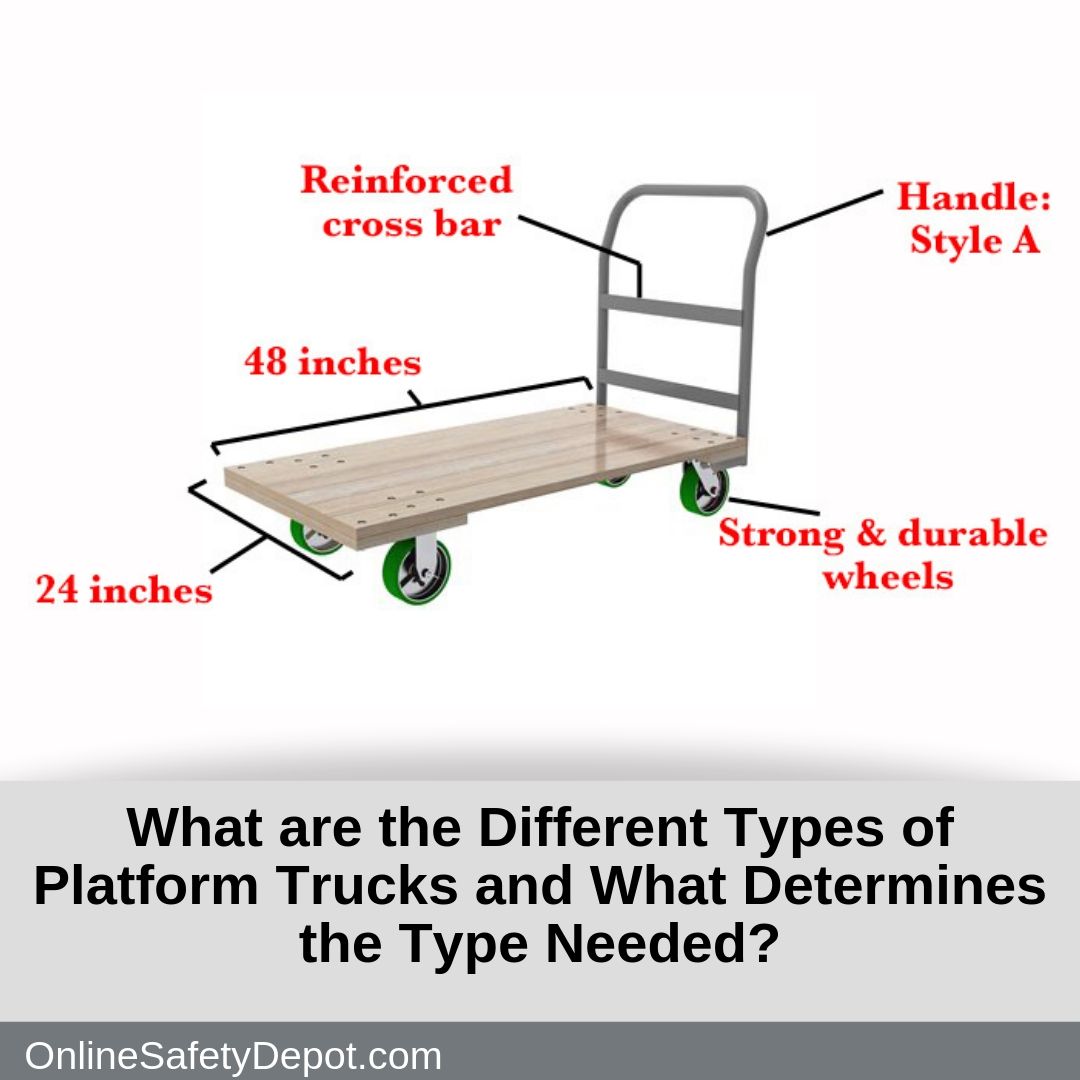

There is such a wide variety of needs among different businesses when it comes to moving product from place to place with the use of a platform truck. Yet, there are many more commonalities in the transport of product and...

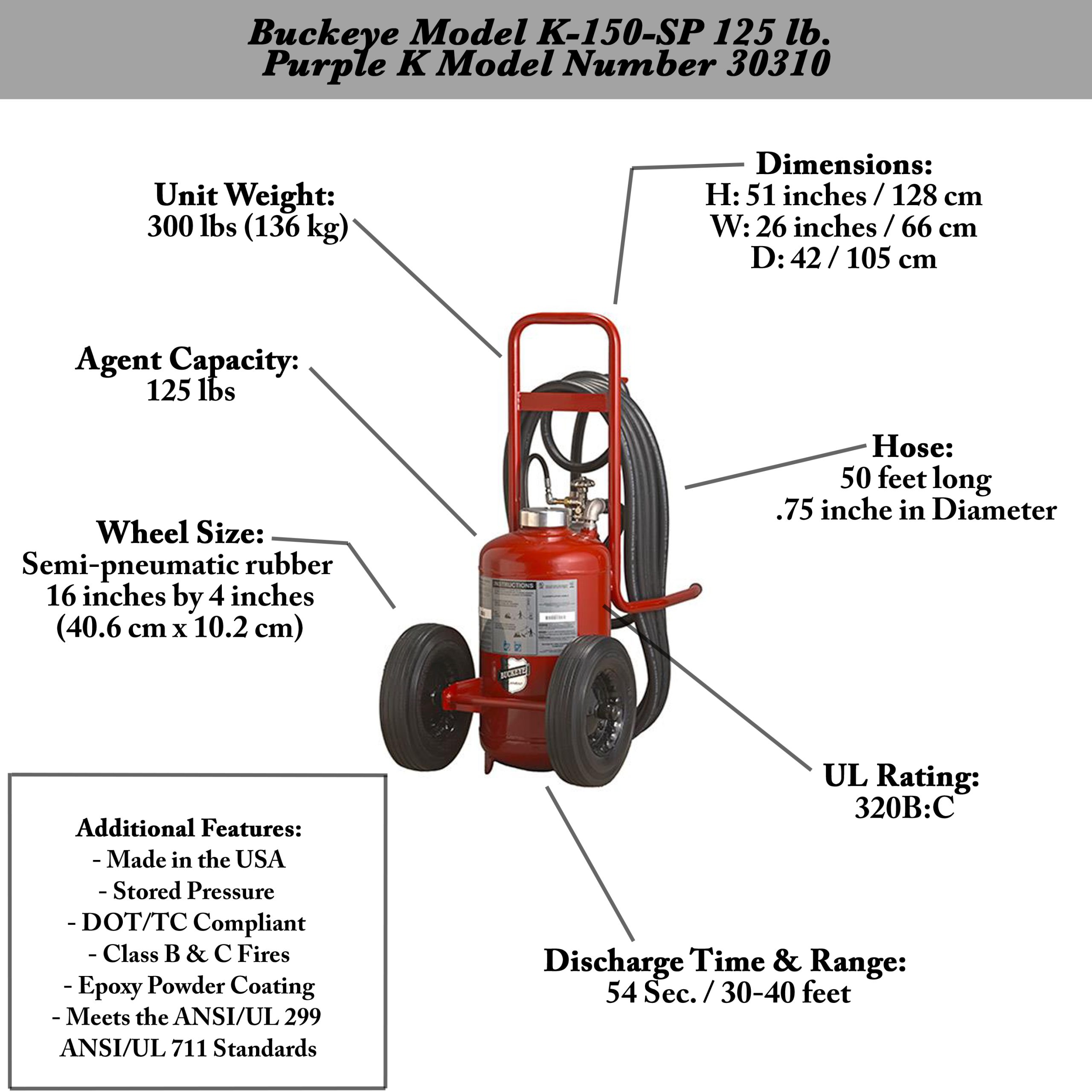

The Buckeye Model K-150-SP is a Dry Chemical wheeled fire extinguishers made by Buckeye. Online Safety Depot carries several models of wheeled Purple K fire extinguishers with the Buckeye Model K-150-SP being the most popular. Designed with a 50-foot hose,...