Kevlar Properties and Behind Armor Blunt Trauma (BABT)

History

Kevlar was discovered in 1965 by a complete accident. Stephanie Kwolek, who was working at Dupont, was using low temperature to create synthetic lightweight fibers that could potentially replace the steel in racing tires, when she found a strange chain of thin molecules with exceptional strength and stiffness. The product was branded as Kevlar and became available by 1971.

How is Kevlar Manufactured

Kevlar is a manufactured plastic, and it’s made of a chemical compound called poly-para-phenylene terephthalamide. This chemical is made from creating a chemical reaction between an acid and a chemical solution containing nitrogen and hydrogen. This process results in chemical chains composed of hydrogen, carbon, oxygen, and nitrogen. These chains naturally form small straight “rods” on the molecular level. These chains are incredibly strong on their own.

Once the chemical compound has been made, the resulting solution is then “spun” while the solution is still wet, yet highly viscous. The spinning process orients all of the chains to be parallel, while enabling the hydrogen bonds on the sides of the chain to act as a glue, keeping the chains together. As such, the chains are incredibly strong in tensile strength along the length of the chain, and the hydrogen bonds form incredible tensile strength perpendicular to the orientation of the chains.

Kevlar in Protective Vests

By the mid-1970’s, the National Institute of Justice (NIJ) began incorporating Kevlar body armor into their ballistic testing standards. In 1976, the first all kevlar vest was created by Richard Davis, who names the vest model Y, that helped pave the way for creating a more concealable and lightweight body armor.

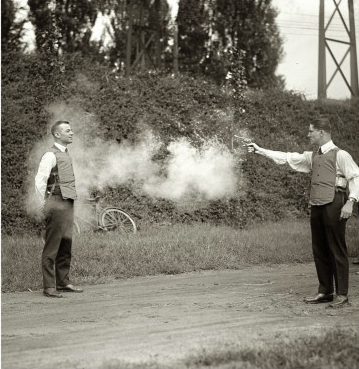

Kevlar’s early designs had its shortcomings, as large fragments or high velocity rounds hit the vest, the energy generated could cause life threatening blunt trauma injuries to vital areas. The term Behind Armor Blunt Trauma (BABT) is the non-penetrating injury resulting from a rapid deformation of armors covering the body.

BABT (Behind Armor Blunt Trauma) from Kevlar Vests

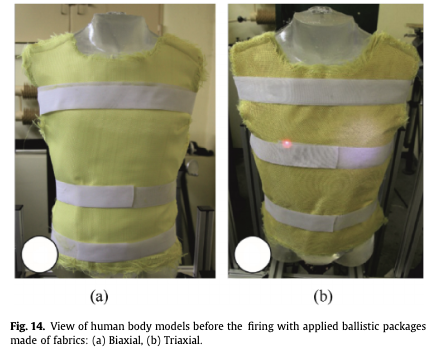

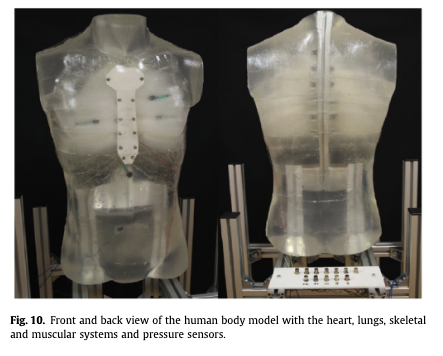

In July 2022, Researchgate.net published an experimental study of BABT impacts, while using 29 layer kevlar, both biaxial and triaxial fabrics. The experiment evaluated impact from a Winchester 9mm FMJ Parabellum round, and focused on five selected areas on the body considered critical, from the point of maintaining a human’s vital function.

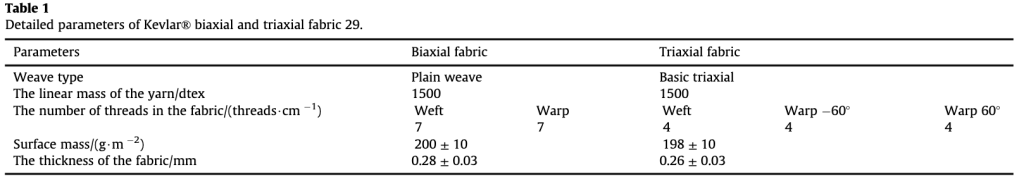

The two kevlar fabric parameters (Biaxial and Triaxial) are shown below in table 1. The triaxial woven kevlar fabrics is composed of three sets of yarns, which intersect and interlace with each other at 60 degree angles. The biaxial kevlar fabric is composed of two layers of unidirectional fiberglass placed 45° to the ‘0’ axis off the roll.

The five locations, on the body that were studied were the sternum on the heart position line, ribs, intercostal space on the lung position line, line of the liver, and the line with the location of the small and large intestines.

Summary and Results

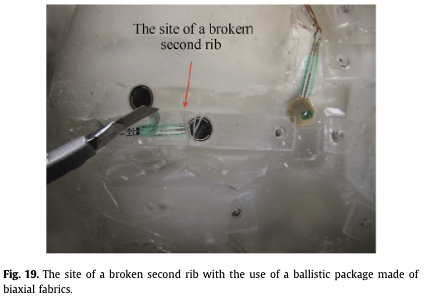

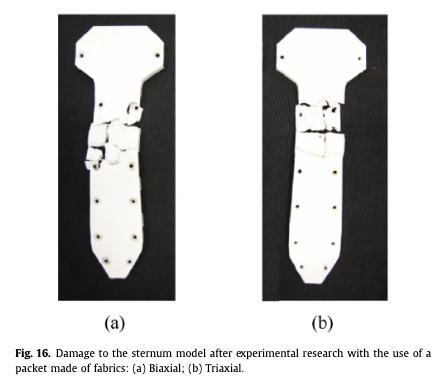

In conclusion, BABT in kevlar vests can lead to a wide variety of injuries, ranging from minor, non-life threatening injuries (with no significant consequences for those affected) to significant, potentially fatal injuries. However, it is assumed that the geometric structure of the fabric has a significant influence on the maximum pressure amplitude. When the bullet hit packages made of biaxial fabrics, the pressure was more localized and covered a smaller area of the human body model, which resulted in greater pressure at the point of impact. However, for the second variant, the acting pressure force of the packages made of triaxial fabrics was distributed over a larger area, resulting in a lower value of maximum pressure at the point of impact of the bullet. It should also be noted that the blunt BABT trauma caused by hitting the sternum along the line of the heart showed sternum fractures using both the packages made of biaxial and triaxial fabric. The number of cracks and the area of damage to the sternum were smaller when using the ballistic packages made of triaxial fabrics. As a result of breaking the anatomical continuity of the sternum, the internal structure of the chest (e.g. lungs, heart), covered by the sternum, may be damaged.

References: